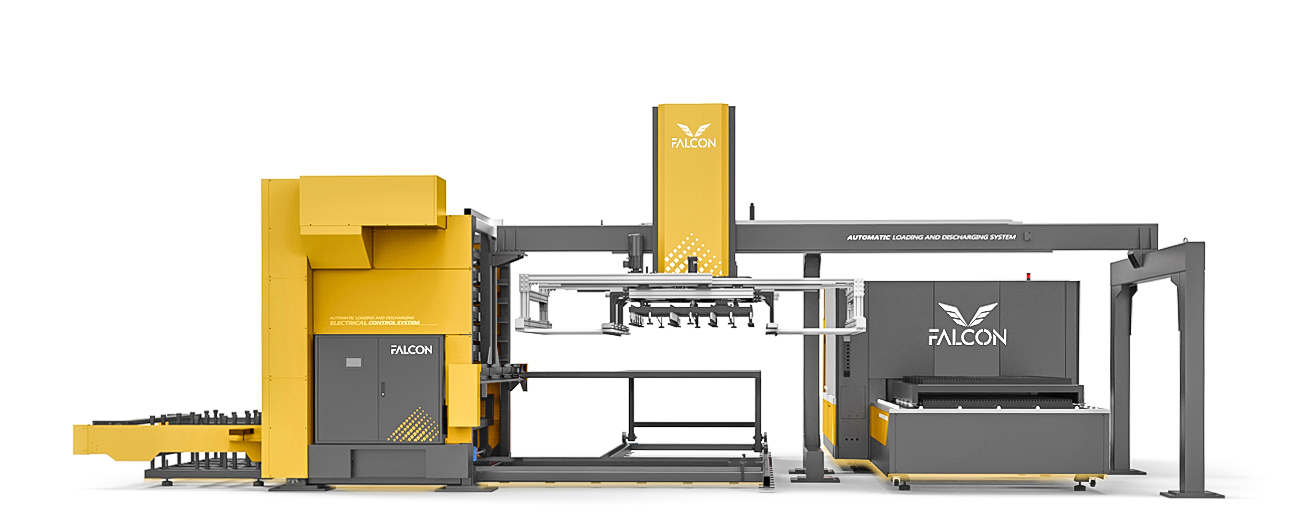

FALCON SAT Masterline

Fiber laser cutting technology for sheet metal processing is constantly gaining popularity in the manufacturing sector, replacing traditional, outdated cutting methods in production processes. This technology offers precision, flexibility, and high-speed suitable for even the most advanced industries. It is extensively applied in sectors such as aerospace, automotive, defense and military, medical devices, electronics, petrochemical refining, communications, energy, automation, and outsourcing.

To ensure the superior quality of our fiber laser sheet cutting machines, we exclusively collaborate with leading manufacturers of top-tier components.

FALCON S machines are equipped with IPG fiber sources and Precitec 2D/3D laser heads featuring Auto-Focus systems, ensuring unparalleled cutting precision. A standout feature of our technology is the capability for 45-degree bevel cutting, complemented by an innovative waste-free cutting system.

Masterline range of devices integrate components from renowned companies such as IPG, Precitec, Beckhoff, HIWIN, Yaskawa, Atlanta, Siemens, Schneider, Gudel, Herion, Neugart, and Panasonic, among others.

A brief summary of the most vital components used by FALCON Laser, authorized by global TOP-TECH control agencies. Final specifications depend on the chosen model configuration.

| Component | Manufacturer |

|---|---|

| Fiber laser source | IPG |

| Laser head (2D/3D Auto Focus) | Precitec |

| Servo drives | Yaskawa |

| Control system | Tmotion |

| Software | CypCut |

| Nesting | CypNest |

| Electrics | Schneider |

| Pneumatics | SMC |

| Linear guides | HIWIN |

| Racks & Pinion drive | HERION |

| Bearings | NSK |

| Gear motor | NEURGART |

| Voltage stabilizer | VolREG |

| Light curtains | SafeGuards |

| Cooling system | S&A |

| Fume filter | SANCH |

| Exchangeable table | Hydraulic |

FALCON fiber laser sheet cutting machines are among the industry leaders in advanced fiber laser cutting solutions, designed to meet the dynamic production needs and trends in the evolving market of fiber laser metal processing. Final features depend on the chosen model configuration.

Technical parameters of each fiber laser sheet cutting machine depend on the chosen model configuration. Final specifications are predetermined in our commercial offers. For further information, please contact us.

Join our world of exceptional industrial products and outstanding services. Are you interested in partnering with us and expanding your business? For more information about FALCON range of products, please feel free to contact us via our online contact form.